Matilda has always been interested in the way things work - how they're made, how they run, and how they can be improved. She's spent her career working in the automotive industry, where she's gained experience in engineering and product development.When she's not at work, Meaghan enjoys spending time with her family and friends. She loves going on road trips, trying out new restaurants, and exploring new parts of the country.

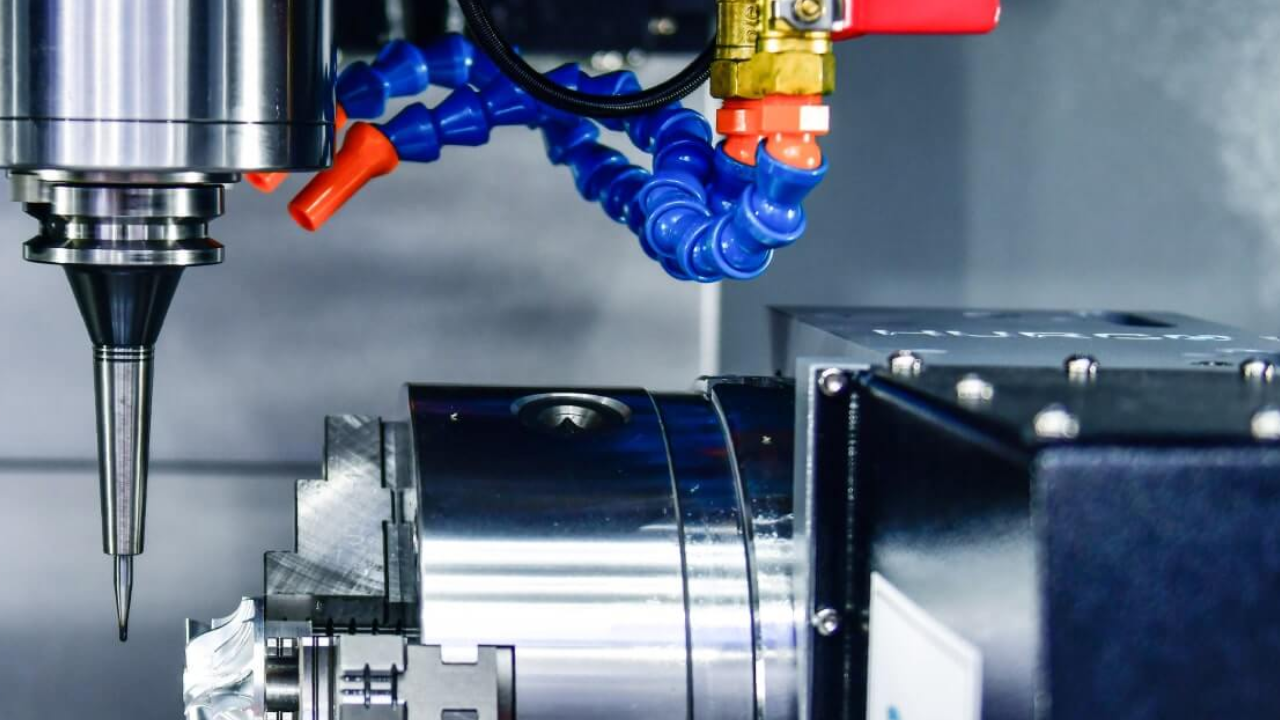

CNC machining has revolutionized the industrial industry by being synonymous with efficiency and precision in the production of complex parts and components. Careful material selection is essential to the success of CNC machining since it has a big impact on the end product’s usefulness, quality, and longevity.

This thorough book delves into the wide range of cnc machining materials that can be machined with a CNC machine, including plastics like nylon and acrylic, metals like titanium, stainless steel, and aluminum, and sophisticated composites like carbon fiber-reinforced polymers (CFRP).

Every material has a different set of characteristics, difficulties, and uses when it comes to machining, thus getting the best results requires a sophisticated understanding. The selection of materials becomes more and more crucial in pushing the frontiers of innovation and reshaping the face of contemporary manufacturing as technology develops.

Metals Are Frequently Machined With A CNC Machine

Because of their availability, machinability, and mechanical qualities, a variety of metals are frequently employed in CNC machining. Among the metals that are frequently utilized are:

Aluminum:

Because of its incredible machinability, low weight, and corrosion resistance, aluminum is one of the most widely used metals in CNC machining. Because of its adaptability, it can be used for a variety of purposes, including consumer electronics, automobile parts, and aerospace components. Aluminum alloys from the 6000 families, such as 6061 and 6063, are frequently utilized in CNC machining because of their well-balanced strength and machinability.

Stainless Steel:

Known for its remarkable strength and resistance to corrosion, stainless steel is a top option for CNC machining applications in sectors like aerospace, automotive, and medical. Grades 303, 304, and 316 of stainless steel are frequently utilized; they differ in terms of mechanical qualities, corrosion resistance, and machinability.

Brass:

Having a golden look and excellent machinability, brass is a copper-zinc alloy. It is frequently utilized in CNC machining for precision parts, electrical connectors, and ornamental elements. Because of its superior corrosion resistance, brass can be used in applications where moisture exposure is a problem.

Copper:

The preferred material for components in electronics and electrical applications, copper is prized for its strong thermal and electrical conductivity. Despite being softer than many other metals, copper can be machined to a high degree of precision with the right tools and cutting methods. Brass and bronze are examples of copper alloys that are CNC machined for improved qualities.

Steel:

Carbon steel and alloy steel are two popular varieties of steel that are utilized extensively in CNC machining. A variety of applications can benefit from the low cost and simple machining of carbon steel, such as that found in 1018 and 1045. Because alloy steels like 4140 and 4340 have better mechanical qualities, they are frequently used in more demanding applications including industrial, automotive, and aerospace machinery.

Titanium:

Because of its excellent in terms of biocompatibility and strength-to-weight ratio, titanium is preferred in the aerospace and medical industries. Despite its reputation for being difficult to machine, titanium is now more widely available because of developments in CNC machining technology. Titanium alloys with a balance of strength, resistance to corrosion, and machinability are widely utilized. One example is Ti-6Al-4V.

Nickel Alloys:

Nickel alloys, such as Inconel and Hastelloy, are renowned for their exceptional corrosion resistance, strength at high temperatures, and longevity. These alloys are used in the harsh environments of the chemical processing, aerospace, and marine sectors. While nickel alloys can be challenging to machine, the end products often justify the effort due to their exceptional performance in harsh environments.

Conclusion

The wide range of metals that are frequently used in CNC machining, such as alloys of nickel, copper, steel, titanium, aluminum, and stainless steel, give manufacturers a lot of possibilities to satisfy the demands of different applications. Technological developments in machining keep making dealing with these materials more feasible, which guarantees the industry’s continuous expansion and innovation in CNC machining.