Matilda has always been interested in the way things work - how they're made, how they run, and how they can be improved. She's spent her career working in the automotive industry, where she's gained experience in engineering and product development.When she's not at work, Meaghan enjoys spending time with her family and friends. She loves going on road trips, trying out new restaurants, and exploring new parts of the country.

Probably one of the most critical processes in any production line is efficiency, and one machine that can help in this regard is the Masterwork automatic die cutting Machine. As we all know, it improves both the accuracy and the tempo of the operation but, at the same time, it presents the great opportunity of increasing the yield on the product markedly.

For folks dealing with packaging, textiles, or any other segment that uses die cutting, the proper usage of some techniques can indeed matter. The article highlights three important methods that will aid you in getting the best yield out of your die-cutting machine.

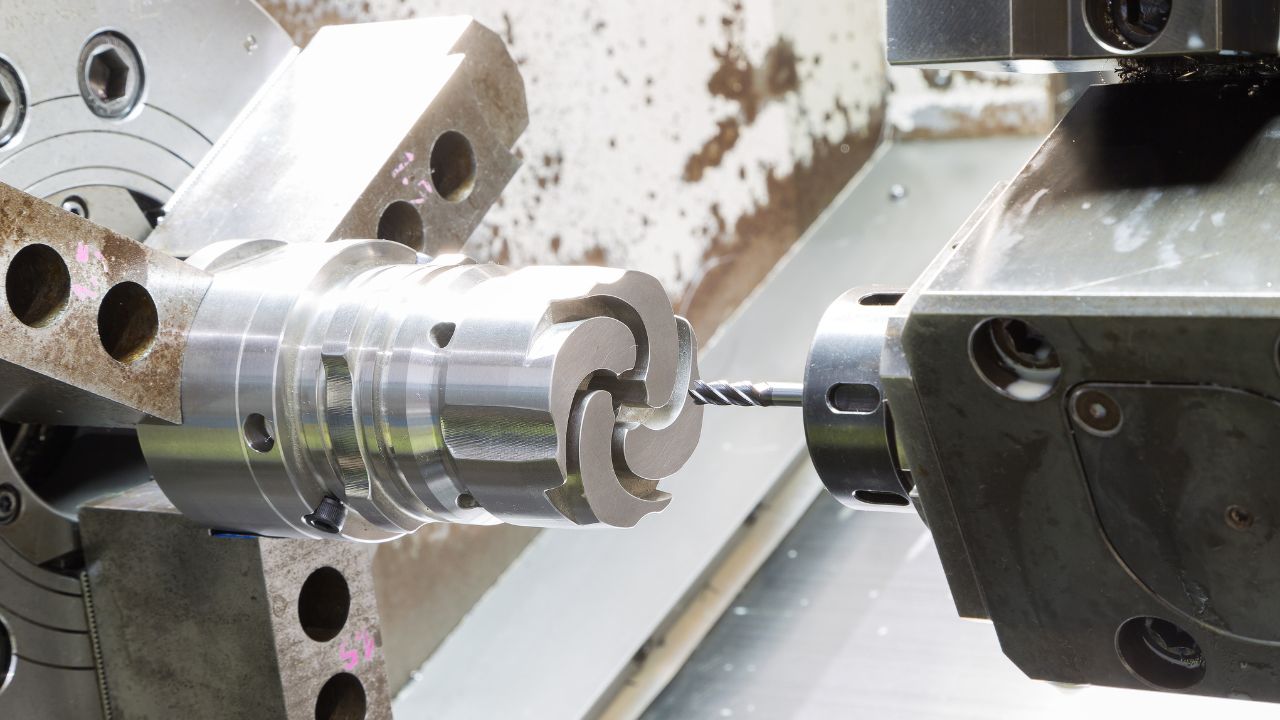

1- Awareness of Automatic Die Cutting Machine’s Construction and Operation

One of the most important things you need to understand is the machine structure and how the different components are connected within the work. The die-cutting machine comprises a main body that offers support to the entire machine.

Then there is the feeding section from where the materials flow inside the machine. The control systems consist of sensors, screens, and other controlling boards from where you can monitor what happens with the material. Next, there is a transmission unit to adjust speed and precision. Lastly comes the cutting dies, which perform the cutting process.

As for the operational sequence, every die-cutting machine is powered on. After that the speed of the production is adjusted, followed by the material loading phase. Next, the cutting phase begins. When completed the cut piece is inspected (readjustments are made if necessary) and after the production, the machine is powered off.

2- Understanding The Die-Cutting Tools

The right choice of die cutting tool is essential to maximize the product yield for box-making machines. Experts recommend opting for materials such as HSS or hard alloys based on the kind of paper and its thickness– the corrugated or thin type.

Tool arrangement must align with the machine’s specifications and product design, considering shapes and functions to ensure precision and consistency. Longer tool life enhances efficiency and yield; factors influencing this include the tool’s material, design, and manufacturer expertise. Tools from reputable European or American brands often offer better durability.

Additionally, maintaining a steady operational speed and avoiding extremes can extend the tool’s lifespan. Another preventive maintenance is cleaning and sharpening the tools to ensure their good working conditions. Purchasing from reputable manufacturers and choosing well-designed machines also help in attaining high product yield and durability of the tools.

3- Paying Attention To the Components Directing Yield

In a die-cutting machine, several key components significantly impact product quality and efficiency. Here is a breakdown of each:

The Feeder: It ensures precise paper or cardboard alignment, and with its adaptability to various paper types it promotes overall yield.

The Gripper Bar: The component accurately guides paper into the machine, preventing misalignment and allowing rapid adjustments for high-speed production.

The Die Cut Steel Plate: It provides essential support for cutting tools, with high-quality materials like German TSH steel ensuring durability and consistent performance.

The Suction Or Blowing Device: It stabilizes the paper during feeding, prevents misalignment, and enhances flexibility for better folding quality. Each component plays a crucial role in maximizing product yield and efficiency.

The Bottom Line

To increase product yields of an automatic die cutting machine, the understanding of machine operational complexity, die-cutting tools and yield-dictating components can make an enormous difference.

Adhering to these practices will also help avoid excessive waste and optimize the production process, skyrocketing the company’s revenue.